Now that we have a firm grasp on bobbins, let’s cover the part of the machine required to use them – bobbin cases.

What is a Bobbin Case?

As the name implies, a bobbin case is the part of the machine that holds your bobbin when you are sewing. There are two classes of bobbin cases (which I mentioned, but did not explain, in the previous post), “removable” and “inset”.

How Do They Work?

A bobbin case, when used with the correct bobbin, will hold the bobbin snugly in place, which will allow the machine to neatly unravel it.

The bobbin case also adds tension to the bottom thread, much like the tension assembly for the top thread. You should never have to adjust the bobbin case tension as the user, so I will not be covering this. This is why it is important to thread the bobbin correctly – when you pull the bottom thread up, there should be resistance on it. If there is not, re-thread the bobbin through the bobbin case.

The top thread will go across the top of the bobbin case, which is why it is so important to use the correct bobbin. If the bobbin is too tall (see my previous post), the thread will catch and seize the machine.

In machines with an automatic thread cutter, the bobbin case also helps keep threads in place to cut. I will cover this in more detail below.

Removable Bobbin Cases

Removable bobbin cases are meant to be taken out of the machine when you replace the bobbin. These can be “front loading” or “side loading”. There are a few models of sewing machines that are “reverse loading”, but these are very rare. All removable bobbin cases will have a lever or spring that can be held to help remove and replace it.

Front Loading

Front loading bobbin cases are removed and inserted on the side of the sewing machine facing the user. These are the most common on modern machines with a removable bobbin.

Side Loading

Side loading bobbin cases are very similar to front loading. It is important, however, to note that side loading bobbins have a smaller hole at the top of the machine. The needle of your sewing machine will dip down into this hole. A side loading bobbin case cannot be used in a front loading machine, but front-loading bobbin cases CAN be used in side loading machines. These bobbin cases are somewhat rare in modern (after 1980) machines. Many older machines such as Kenmore, Singer and White have this style.

Things to Consider

The most common removable bobbin case is called a “15 Class” bobbin case. If you read Part One of this guide, you’ll notice a similarity in names. These bobbin cases are meant to be used with Metal 15 Class bobbins, unless otherwise noted. There are a few variations of this style bobbin case, but they will always be noted.

Inset Bobbin Cases

Inset bobbin cases, or “drop-in” bobbin cases, are more common in modern machines. These bobbin cases do not have to be removed from the machine to replace the bobbin. Generally, the customer should never need to take these bobbin cases out. These style bobbin cases face up (sometimes at a slight angle) and are usually right on the sewing surface.

Metal Bobbin Cases

Metal bobbin cases are usually used with metal bobbins. These are more common with older sewing machines; it is very rare to see a metal inset bobbin case in a modern residential sewing machine.

Plastic Bobbin Cases

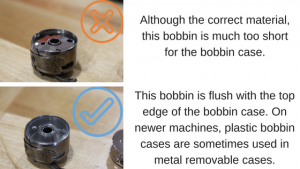

Plastic bobbin cases are usually used with plastic bobbins. There are many different styles of plastic bobbin cases, so it is important to check your model number when looking for replacements. If your machine is equipped with an automatic thread cutter, you may notice a rectangle with felt-like material on it. Do not attempt to remove this – it is required for the thread cutter to function properly. These bobbin cases also typically have a small metal “finger” on the right side – be gentle with this piece, as it can be bent.

Bobbin and Bobbin Case Fit

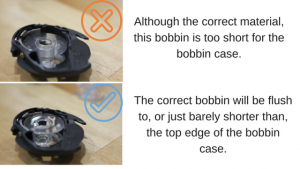

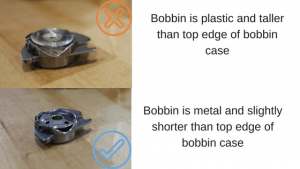

Let’s backtrack for a moment to my previous post. Perhaps you have more than one sewing machine – which means you need more than one type of bobbin. How can you determine which bobbins belong to which machine? You can, of course, look up your machine to determine the bobbin style. Or, you can take a slight shortcut. Below are some examples showing bobbins that do and do not fit in bobbin cases.

I hope this primer on bobbins & bobbin cases helps you understand how your machine functions. In the future, I will cover more parts of the typical sewing machine – if you want to see something in particular, let me know!

Next week, I will be covering the dreaded tension assembly.

-Sarah

s. cook says

Hi Sarah,

Thanks for a great post.

I have a Singer 247 and sometimes the top thread goes under the bobbin case – like the one pictured above on the right – and gets tangled up.

I’ve turned the hand wheel slowly and watched as the top thread comes around once then the a second time only to go under the bobbin case

Funny thing is I can sew for a while and it’s okay then the machine will stop and thread will be jammed up…

I’ve rethreaded and rethreaded; adjusted the tension of top thread; taken the bobbin case out and cleaned up the stray threads and lint and reassembled …

Any ideas???

Sarah says

Hi! Have you tried a different bobbin? Make sure you have either a plastic or metal 66 Class bobbin in your machine – a 15 class will definitely mess it up! If you are using a 66 Class, try one or two different bobbins of the same style. You may have a defective bobbin that is causing issues.

Make sure you’re using machine thread (avoid anything that says “hand” in the thread description).

Although it is unusual, it is also possible that you have a defective or broken bobbin case. It is pretty unusual for metal ones to break or otherwise fail, but it is not unheard of.

If these things don’t fix the problem, you may have an adjustment that is off – I would bring it to your local sewing machine repair shop.

Mel says

My bobbin case seems to be cutting my thread. What is the problem? Thread is good stuff, threaded and needle set good, bobbin set correctly. Timing seems ok as it picks up the bobbin thread but it cuts the top thread when making its full rotation.

Sarah says

Hi Mel, sounds like the thread is getting caught somewhere. The three most common areas for thread to get caught are on the bobbin case, the presser foot and the needle plate. Check all three of these spots for any sharp edges or rough spots, and either replace or smooth the components down. It is still possible that the timing is off just enough that it catches the thread, but does so too late and causes excess tension on the thread. Hope this helps!

Kerrie Danner says

Have a Commercial singer sewing machine 2491. Can not find a bobbin case for this sewing machine, is there one that will be compatible ?

Sarah says

Hi Kerrie,

Looks like the bobbin case for that machine is no longer made. In cases like these, I recommend contacting your local repair shop to see if they have any old stock of them, calling Singer directly, or searching ebay/craigslist for a used one. Unfortunately, those are really the only options for tracking down parts like that. I hope you find one!

JENNIFER L DILAPI says

I have the singer quantum xl-1. One day as I picked up my bobbin case to install the bobbin, it fell apart in my hand. The clamp fell off. I got it back together, but I’m not sure if there’s parts missing that may have fallen off. It seems really floppy and doesn’t snap into the machine securely. I can’t remember now if it ever did. But ever since, the bottom thread tangles and gives me an awful time. I’ve adjusted tension on top and bottom so many times, and threaded and re-threaded, bought new thread, and now needles are getting bent at the tip. I’ve gone through multiple needles. My next step is to try and replace the bobbin case but I’m not sure exactly which bobbin case I need. Can you help? How do I find this out? Tia

Sarah says

Hi Tia,

Looks like that machine has a bobbin case that is somewhat uncommon. Your best option is to contact Singer directly or go to a trusted repair shop. If that doesn’t work, you could always Google your machine + “bobbin case” to see if you can find the part. Hope this helps!

Kate says

Hi Sarah, I have a Pfaff machine. I had to change/refill a bobbin, and since then, I can’t seem to get the thread to unspool properly from the bobbin once it’s inside the bobbin case. I’m not even talking about in operation which of course doesn’t work. I mean the thread won’t pull through the bobbin cover with a reasonable tension. I’m certain I have the correct bobbins – what am I doing wrong?!?????

Sarah says

Hi Kate! If you have a removeable bobbin case in your machine, try flipping the bobbin in a different direction. If that doesn’t help, gently push a needle underneath the bobbin case spring. There may be some thread or lint stuck in the spring that is preventing the thread from pulling through properly. If your Pfaff doesn’t have a removeable bobbin case, there’s not much I can suggest beyond taking it to a trusted repair shop or dealer. Also, make sure that you don’t have a thread tail from winding the bobbin! If there’s a little thread on the top or bottom of the bobbin that is remaining from winding it, it can get caught on the bobbin case. I hope this makes sense and helps you out a bit!

Jackie says

Hi Sarah, I have a Morse 5201 and lost my bobbin case, are there any that are interchangeable with this machine

Evelyn says

Hi Sarah .. I have a brother sewing machine. My thread keeps tangling down the fabric and the feed dogs catches my fabric. When I remove the part down to see how the machine is threading, I realized an area underneath the bobbin case has been slit by the thread so the thread holds up there. This is a new sewing machine just five month old. I have search online to see the cause of my problem but I can’t make sense of the information I get. When i called my local repair shop to see what my problem is, he just smoothing that area under the bobbin case . It worked for sometime and few days later started again. Do you think is the broken bobbin case and it needs to be replaced?

Sarah says

Hi Evelyn, did this issue start after you changed thread? The technician you spoke with recommended the same thing I would typically recommend. Without seeing it, I’m not sure if your bobbin case is broken/split. I would check out my post Sewing Blunders and How to Fix Them to make sure that you have appropriate tension on your machine! Sometimes if the top thread isn’t in the tension properly, it won’t pull the thread up enough, causing catching underneath. Try that first, and if all else fails, try calling Brother directly. Your machine is pretty new, so I’m sure they’ll be willing to work with you on a solution, even if that means sending you a new bobbin case.

Sarah says

Hi Jackie, it appears to me that your machine takes a 15 class metal bobbin case – thanks for your question!

Sherry Sopoci says

Hi Sarah,

I am so happy that I found this post, thank you so much for creating it.

I Sew for a living and I use a singer quantum. I have problems with my thread bunching in the back of the fabric. When I take my machine in the repair guy says a have burrs that need to be filed down, what am I doing wrong? My repair guy suggests that I find a machine that has a metal bobbin case.

Can you recommend a good sewing machine that has one? I don’t want to spend too much, some machines you would have to take out a second mortgage on!!!

Thank you,

Sherry

Sarah says

Hi Sherry, sorry to hear you’re having issues with your machine. Unfortunately there’s not much you can do to prevent burrs from showing up on your bobbin case, especially if you’re sewing on heavy fabric or a lot of layers. They will eventually show up with any normal use of a sewing machine, as the needle will occasionally deflect – this isn’t normally a user error, it just happens sometimes. Just in case, I would check our troubleshooting post and make sure that your top thread is properly in the tension, as this can sometimes worsen the problem and make it more likely to mar your bobbin case. As far as a replacement, I always recommend old (at least 30 years) Singers and Kenmores to anyone looking to sew either heavy fabric, a lot of layers, or very often. They tend to hold up longer and are more well-equipped to handle heavy fabric and use. If you’d rather look for a new sewing machine to replace it, we recommend checking out some local dealers and getting more information that way. Everyone has very specific sewing needs, and spending the time to do research and test out potential options is extremely valuable.

Bethany says

Hi! The hinge that hold my bobbin case in place is loose and won’t hold. Is there a place to buy that replacement part? The screw on the hinge appears stripped too?

Sarah says

Hi Bethany,

There’s a few small parts in bobbin cases that can fail – replacing the entire thing is normally the best solution. The screws and springs are very specialized and therefore fairly expensive on their own. Check your local sewing machine dealer if you have one, or do a Google search for “[machine make and model] bobbin case”. Hope that helps!

Jah says

Hello! I’m very new to sewing so please excuse me if this doesn’t make total sense. I have a Singer Merrit 3130 and had to remove the bobbin case to adjust the metal plate under it because my needles kept hitting it. I’ve found myself unable to reinsert the bobbin case. Any input would help tremendously!

Sarah says

Hi Jah, I’m not quite sure what metal piece would require you to take the bobbin case out for. There are a few metal plates that are adjustable in that area, but you shouldn’t need to remove the bobbin case to adjust them. It sounds likely that the escapement is adjusted too narrow to allow the bobbin case to be replaced. Unfortunately, that is not something I am able to help with over the internet – I recommend bringing your machine to a trusted repair shop to get it working the way it should.

Albert says

Thanks for the good explanation. I have linked to this article from my site: https://www.sewingmachinerepaircentre.co.nz/pages/glossary

Sarah says

Hi Albert, thank you for sharing! Regards from across the Pacific!

Robin says

I have a four month old Juki HZL F600. It has been great until this week. Bobbin thread is seen on top, missed stitches and squirrel nests on bottom of fabric.

I have rethreaded, rewound bobbins, adjusted pressure foot and needle tension. I cleaned out the bobbin case of lint, and nothing helps. The bobbin seems to be rattling a bit and my bobbin cutter does not cut. Any idea what to try next?

Sarah Strahan says

Hi Sarah, my grandmother has lost a bobbin case for her what we think is a 1950s Singer machine. I don’t know much about sewing machines, but I’m assuming is side loading? Could you direct me to what to buy for her?

Sarah says

Hi Sarah! Check the machine for a model number – normally on the front plate of the machine. It is possible that the machine is old enough that there is no model number listed – if that’s the case, look for the serial number. It will usually be on the sewing surface of the machine all the way on the right (“under” the stitch length adjustment, if that makes sense). You can then look up the serial number on this website: http://ismacs.net/singer_sewing_machine_company/serial-numbers/singer-sewing-machine-serial-number-database.html and find the model number from it. You will be able to determine which style bobbin case you need based on that – unfortunately there are quite a few different kinds of Singer bobbin cases from that era, so you really do need a model number. I know this is a lot of information, but hopefully it helps!

Sarah says

Hi Robin, I’m sorry to hear about your sewing machine woes! Since the machine is so new, I would try taking it back to a certified Juki dealer. Those three issues together could be a sign of a bad adjustment or something being broken.

Pamela says

Hi Sarah, thanks for all this wonderful information.

I have an Imperial 510. I believe the company was purchased by Janome at some point. The machine is from the 1960’s and was purchased in Montreal. It appears to be in very good condition but I can’t get it going as I have no idea what bobbin it would take. The bobbin case is a J-H2. I guess the good news is I have the bobbin case but no bobbins or manual for that matter. Any ideas as to which bobbin(s) would work for this case? Thanks!

Alice says

Hello! Thank you for your in depth post. I am very new with sewing and I trying to get an old Pfaff 80 sewing machine to work. I noticed the bobbin case missing… Could you help me to figure out what type of bobbin case and bobbin I need? I really have zero knowledge… Thank you very much in advance. I could send pictures and all, and also the manual, which has detailed illustrations but sadly nothing about a certain type of bobbin case. I wish you all the best, Alice from Belgium

Sarah says

Hi Pamela, I can’t find any information on that machine or a J-H2 bobbin case! My first guess would be a 15 class bobbin (especially if the bobbin case looks similar to a 15 class bobbin case)! Give one a try and see how it fits – it should slide in easily to the bobbin case. If not, it’s time to start trying others. Hope this helps!

Sarah says

Hi Alice, I can’t find a lot of information on that machine, but it’s looking like it takes the same bobbin case as a Pfaff 1222 and 1467, which are much easier to find information on. The bobbin case should be 6mm rather than the larger 9mm bobbin case that some Pfaff machines have.

Kimberlie Gates says

I have misplaced my bobbin case for my beloved Brother #XR9500PRW Project Runway model, digital sewing machine, and I’m having a very difficult time finding a recplacement, for it. All my internet research is telling me that it’s supposed to be model #XC3152221′ which is covered in black plastic, and mine was silver, so I’m very sceptical about buying it, without more information, of which I don’t have. Any suggestions, or advice would be greatly appreciated. Thanks!

John j conway says

Hello, I love this article. The last mystery of the sewing machine explained. Not really as I don’t get how the fork for reverse works. I do have a question on bobbin operation. The hook picks up the thread and makes a loop. Let’s say we have a front half and a back half of the loop. Needs two halves to be a loop. I can see the front half as it’s directed over the face of the bobbin and gets pulled up by the take up lever. Any chance of explaining what happens to the back half of the loop and what keeps it from wrapping around the drive shaft for the bobbin. I have tried the net and observations and can’t for the life of me figure this one out. Thanks in advance

John conway

Sarah says

Hi Kimberlie! I’m getting that same part number when I reference the model number you mentioned. Does the bobbin case you’re missing look like the 15 class bobbin case?

Sarah says

Hi John! I’m not sure I totally understand the question, but I’ll try! When the needle thread gets pulled by the hook, it actually goes between the hook and the bobbin case (in a top-loading machine). In a front-loading machine (which it sounds like you have), the thread goes around the hook and bobbin case together. However, in a front-loading machine, the hook itself actually “floats” in the raceway, which gives the thread room to go completely around it.